Life Sciences

Point of Care Diagnostics

Medical Devices

Automated Solutions for High-Performance Diagnostic Manufacturing

Applications

Drug Discovery

Kaste dispensing solutions are an excellent addition to high-throughput screening workflows, offering precise and uniform dispensing of reagents for reliable and reproducible results. The combination of accuracy, adaptability, and workflow optimization makes them a valuable tool in accelerating screening processes.

Assay Development

Kaste’s versatility in managing a range of viscosities ensures compatibility with diverse assay formats, while their seamless integration into automated systems allows for efficient and scalable operations. By delivering consistent and reliable performance, our dispensers empower users to tackle diverse assay requirements with confidence and efficiency.

Biosensor Manufacturing

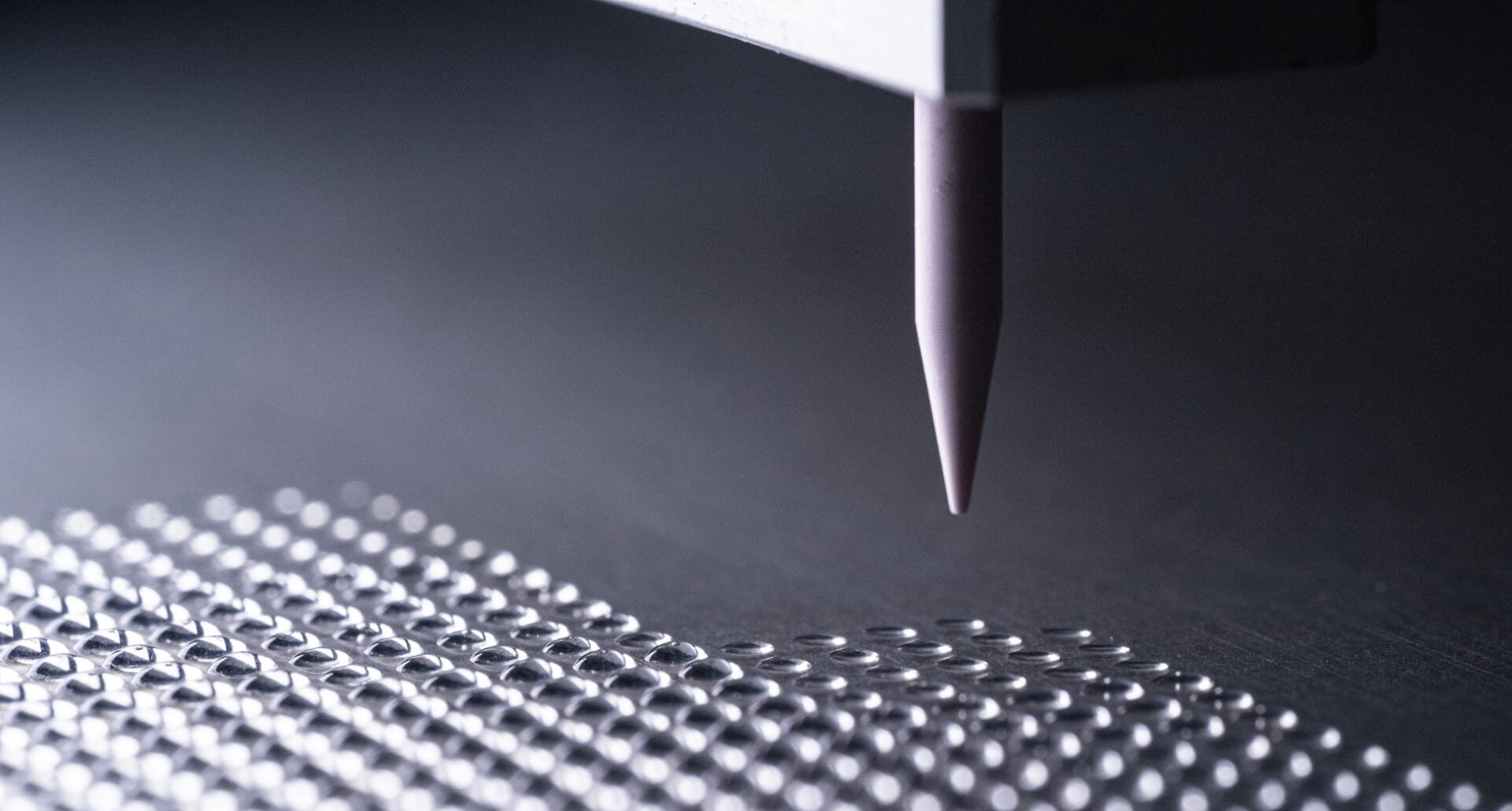

Advanced dispensing solutions enable precise and uniform application of reagents onto biosensor surfaces, ensuring reliable performance and sensitivity. With the ability to handle variable volumes and viscosities, our technology supports the development of versatile and scalable biosensors for diverse applications.

Microfluidic Chip Dispensing

Whether it’s by Kaste’s fully automated Benchtop Solutions or through integration into existing automated workflows, our dispensing solutions are designed for scalability in the microfluidic chip manufacturing space. Precise and accurate dispensing with Kaste ensures consistent reagent application on microfluidic chips.

Lateral Flow Diagnostic Manufacturing

Ginolis’ modular manufacturing equipment provides a versatile foundation for diagnostic and life sciences production. These customizable systems enable seamless integration, allowing manufacturers to expand and adapt workflows effortlessly while maintaining high-throughput efficiency and reproducible quality. Ginolis’ Kaste dispensing solutions complement these systems with exceptional precision and consistency, ensuring accurate reagent deposition critical to lateral flow assay manufacturing and supporting scalable, high-quality production.

Microarray Manufacturing

Ginolis’ Kaste dispensing solutions are ideal for creating microarrays with consistent spot sizes, which is critical for applications such as ELISA assays, DNA, or protein analysis. These assays rely heavily on precise and uniform dispensing to ensure reliable detection and quantification of biomolecules. With Kaste, researchers can count on dependable technology that meets the rigorous demands of high-density microarray production, supporting advancements in diagnostic manufacturing.

News & Insights

Announcing: Kaste Lab

Viscosity Series: What Can Kaste Nano Pumps Handle? Part 2 - Non-Contact Viscous Dispensing

Elevating Precision Dispensing: The Strategic Imperative of Ginolis Kaiku Data Collection

Viscosity Series: What Can Kaste Nano Pumps Handle? Part 1 – Precision, Stability, Efficiency

Viscosity – A Challenge for Low Volume Dispensing?

Ginolis Kaiku: Operational Intelligence for Strategic Manufacturing

Beyond the Drop: Why Dispensing Technology is the Unsung Hero of Modern Industry

How to Choose a Good Dispensing Technology: Cut Costs, Not Corners 💧

Precision in Sample Handling: The Key to Reliable Experiments

Mastering Assay Production: Overcoming Key Challenges in the Lab

Reliable Automation Solutions for Contract Manufacturing

Probot Oy and Ginolis Forge a New Path in Robotics with Preferred Partner Agreement

Introducing Kaiku: New Data Insights in Manufacturing

Introducing Chris Buhlmann: Ginolis’ New General Manager for North America

Ginolis products help our customers to automate their production for high-yield industrial needs with the help of precision robotics.

About us

From Breakthrough Research to First Patient

Bridging the gap between research and full-scale production can be challenging without the right solutions. Ginolis provides automation technologies that ensure high quality and scalability as your diagnostic products move from lab to production. From standard products to fully customized systems, we offer an extensive range of production automation solutions for lateral flow device manufacturing, medical device manufacturing and microfluidic device manufacturing.

-

Research & development

We work closely with our clients to turn ideas into functional solutions through agile product development. Our expertise ensures a smooth transition beyond research and speeds up the journey to production.

-

Building The Bridge

We specialize in bridging the gap between lab-scale innovation and industrial-scale production. Our modular and scalable solutions are tailored to support each stage of your product’s lifecycle.

-

Automated production lines

Our automation systems are designed for precision, repeatability, and flexibility. We deliver turnkey production lines for diagnostics and medical devices, optimized for quality and efficiency.

About Ginolis – Frequently Asked Questions

-

What makes Ginolis dispensing technologies unique?

Ginolis dispensing solutions, like the Kaste Nano Pump, offer nanolitre-level precision with high-speed performance. Integrated pressure monitoring and modular design make them ideal for both R&D and scalable production environments.

-

How do Ginolis solutions support diagnostic manufacturing?

Our technologies are designed specifically for lateral flow and diagnostic device assembly. From precision dispensing to quality control and robotic automation, we help manufacturers ensure consistency, efficiency, and compliance.

-

What is Low-Volume Ultra-Precision Dispensing?

Low-volume ultra-precision dispensing refers to the ability to accurately handle and dispense extremely small liquid volumes—often in the nanolitre to microlitre range—with high repeatability. In diagnostics, this is crucial for minimizing reagent use, ensuring consistent test results, and enabling compact test designs such as lateral flow devices and microfluidic systems. Ginolis dispensing solutions are engineered to deliver this level of precision, supporting both advanced R&D and scalable diagnostic production.

-

What volume ranges can Ginolis pumps handle?

Ginolis dispensing systems are designed to meet the demanding requirements of both research and industrial-scale diagnostic manufacturing. With a wide operational range—from as low as 1 nanolitre up to 1500 microlitres—our systems offer unmatched precision and repeatability across various fluid types and use cases. Whether you’re developing microfluidic prototypes in a lab or managing high-throughput production lines, Ginolis dispensing technology ensures accurate volume control, minimal waste, and reliable performance throughout the process.

-

How do you minimize reagent waste in dispensing?

Minimizing reagent waste in dispensing is a key priority at Ginolis. Our dispensing systems are designed with precision and efficiency in mind to ensure optimal use of valuable reagents. Here are a few core principles we apply:

Non-Contact Dispensing Technology

Our systems use non-contact dispensing to deliver accurate micro-volumes without the need for excess reagent priming or purging, significantly reducing waste.

Precise Volume Control

Ginolis dispensing platforms offer highly repeatable dispensing down to nanoliter levels, ensuring the exact amount of reagent is used—no more, no less.

Automated Calibration and Monitoring

Continuous in-process monitoring and automated calibration help maintain consistent dispensing performance and catch deviations early, reducing unnecessary reagent loss.

Minimal Dead Volume Designs

Our fluidics are engineered to minimize dead volume in tubing and components, ensuring that nearly all reagent introduced into the system is used effectively.

Batch Traceability and Quality ControlIntegration with Kaiku™ provides real-time process traceability and performance data, allowing operators to monitor reagent usage and identify optimization opportunities across batches.