Assay‑Grade Results, One Software‑Defined Benchtop

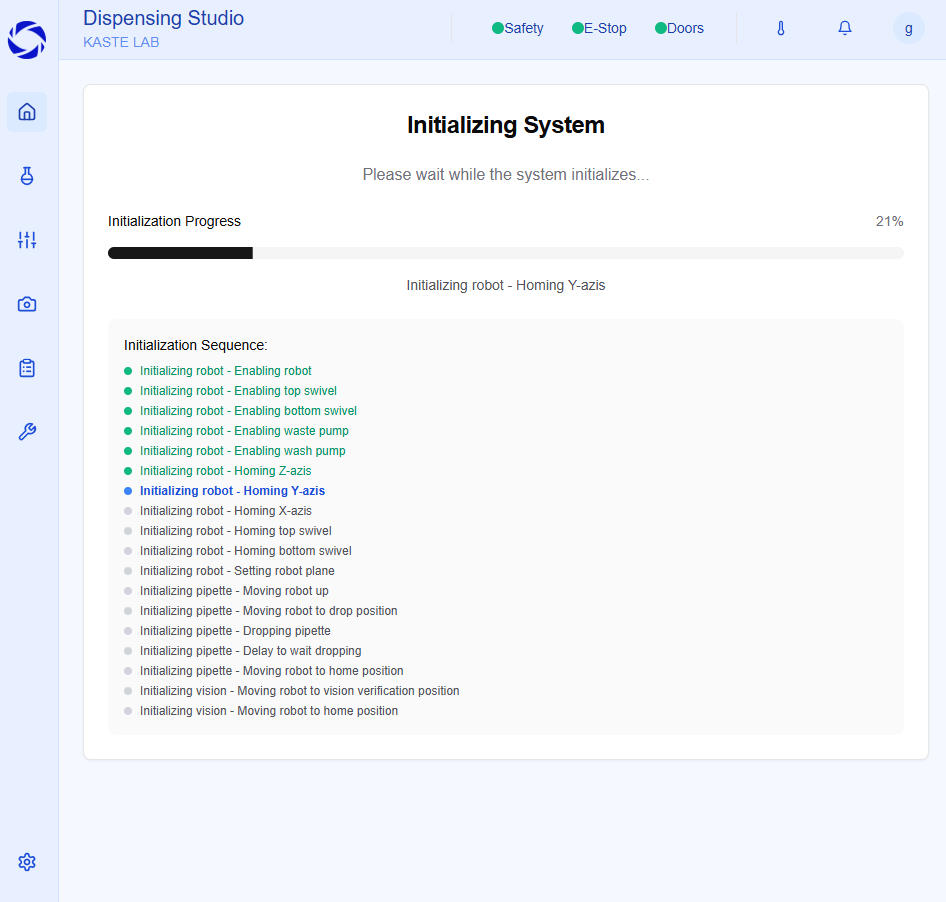

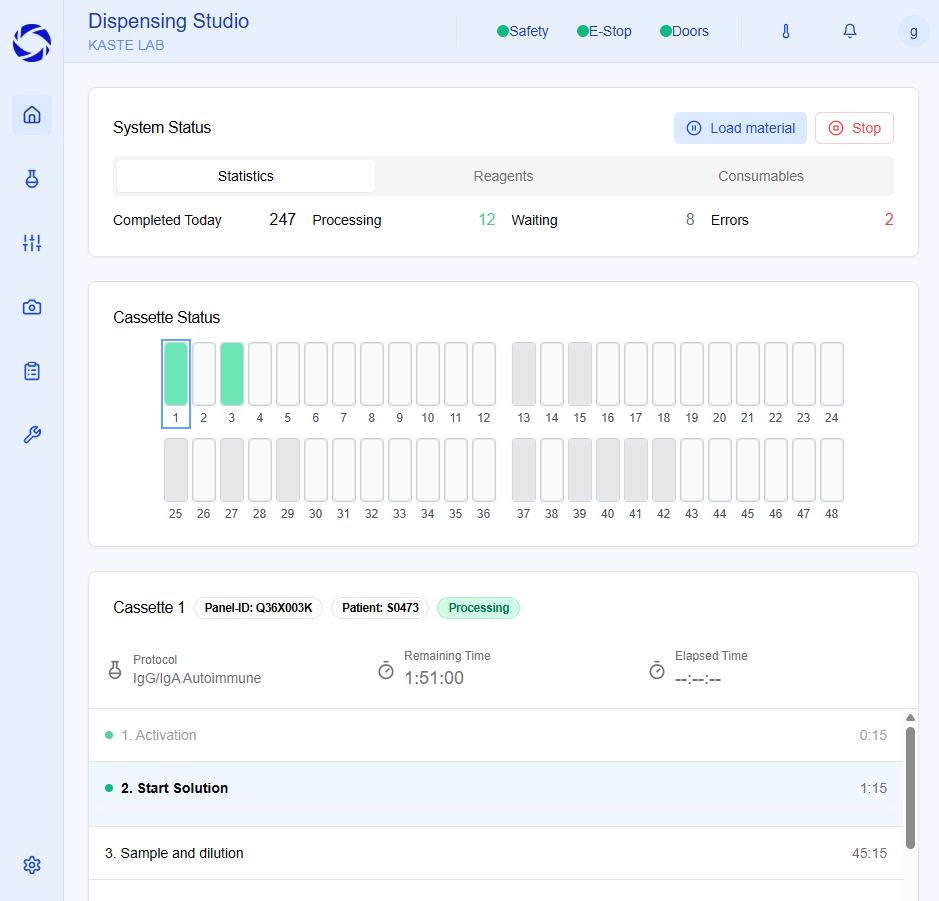

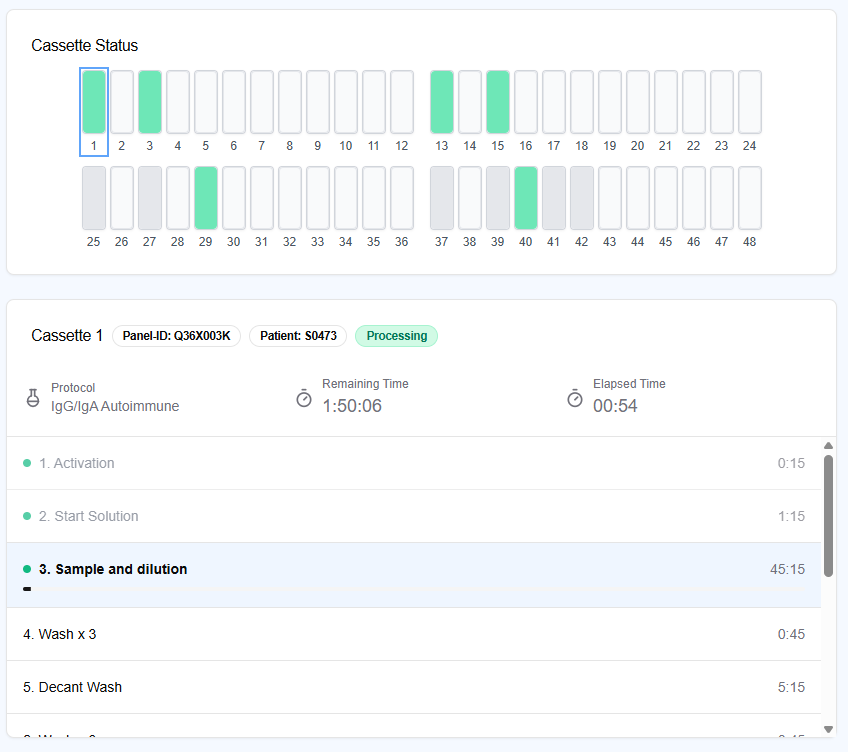

Kaste Dispensing Studio is the central control hub for the Kaste Lab benchtop system, giving engineers full visibility and command over every dispensing step in real time. Through a unified touchscreen interface, users can design and execute protocols, manage reagents and cassettes, tune temperature, motion, and pressure setpoints, and leverage integrated vision and logging tools to verify each dispense, troubleshoot issues, and maintain assay‑grade performance across pumps, fluids, and applications.

What is Kaste Dispensing Studio?

Kaste Dispensing Studio is an application-level control and recipe management software for Kaste Lab, connecting directly and providing a unified interface to configure, execute, and monitor dispensing operations from lab development all the way to automated production cells.

The software guides users through setup of fluids, volumes, timings, and motion profiles, while automatically capturing key process parameters for each run. It is engineered for environments where microliter and nanoliter accuracy, compliance, and repeatability are non‑negotiable.

Why Kaste Dispensing Studio Stands Out

Kaste Dispensing Studio transforms dispensing from a black box into a transparent, controllable process asset. By combining recipe management, live process feedback, and integrated quality checks, it helps teams move from trial‑and‑error to data‑driven dispensing.

With one environment for engineers and operators, method development, scale‑up, and daily production run on the same foundation—reducing transfer risks and accelerating validation. Whether you are developing new assays, filling microfluidic cartridges, or scaling lateral flow production, Kaste Dispensing Studio keeps every dispense consistent and traceable.

With Kaste Dispensing Studio, every drop of your process is defined, controlled, and perfected—driving accuracy, consistency, and confidence in every dispense.

Key Features

-

Intuitive recipe and method management

-

Graphical setup of dispensing recipes, including volumes, speeds, patterns, and sequences.

-

Fluid library with saved parameters for different reagents, viscosities, and use cases, enabling fast changeovers.

-

Version-controlled methods to support development, validation, and controlled updates in regulated environments.

-

-

Real-time control and monitoring

-

Live visualization of key dispensing metrics such as volume per shot, flow profile, pressure, and cycle time for each station.

-

On‑screen status of pumps, valves, axes, and safety states, with clear indicators for alarms and warnings.

-

Fine adjustment tools that allow engineers to tune parameters while observing immediate impact on process behavior.

-

-

Built-in quality and calibration workflows

-

Guided calibration routines for volumes, nozzles, and lines to maintain accuracy over time and across fluids.

-

Optional in‑process checks (e.g. weight, imaging or test shots) integrated into recipes to verify performance before full runs.

-

Automatic logging of calibration and verification events to support audits and continuous improvement.

-

-

Flexible run execution for lab and production

-

Modes for single‑shot testing, small batch development, and fully automated sequences on integrated lines.

-

Easy duplication and scaling of lab‑proven methods to higher throughput platforms without rebuilding from scratch.

-

Operator‑friendly runtime screens with simplified controls, tailored to daily use on the production floor.

-

-

Traceability and data connectivity

-

Comprehensive run logs capturing recipes, parameter sets, timestamps, user IDs, and key process outcomes for each batch.

-

Structured export of dispensing data for further analysis in external tools or downstream quality systems.

-

Optional integration with Ginolis Kaiku for full factory‑level traceability and analytics across dispensing and other processes.

-

-

Designed for Demanding Applications

Kaste Dispensing Studio is built for industries where precision and compliance define success.

-

Diagnostics and lateral flow manufacturing: Consistent line, spot, and fill volumes with documented parameters for every lot.

-

Microfluidic chip production: Controlled nanoliter to microliter dispensing into complex geometries with minimal waste.

-

Biosensors and assays: Reliable, repeatable reagent application across high‑mix, high‑value product portfolios.

By combining advanced Kaste hardware with Kaste Dispensing Studio, you gain a robust platform that scales from early experiments to validated, high‑throughput production.

-

Interested?

We would be happy to talk more

Contact us and let’s talk about your project.