When R&D and production work in silos, manufacturers face downtime, compliance risks, and inefficiencies. Ginolis Kaiku unifies data for real-time visibility, traceability, and predictive intelligence—cutting losses, scaling faster, and strengthening Industry 4.0 operations.

Today’s blog is 500 words long, and a 5 minute read.

The Hidden Cost of Disconnected Operations

Modern production lines generate mountains of data—terabytes each day. Yet much of that information never becomes insight. Why? Because R&D and production often operate like islands, separated by a wall of systems, processes, and accountability. What’s learned in development is rarely visible to production. What production uncovers in real time rarely flows back to R&D.

This disconnect is expensive. Unplanned downtime can cost up to $2M per hour. Quality deviations slip through until late in the process. Compliance demands add friction. The result: lost efficiency, lost margin, and lost trust from customers and regulators.

Kaiku Breaks Down the Wall

Ginolis Kaiku is designed to unify—not just collect—data across your entire manufacturing ecosystem. It’s a cloud-native operational intelligence platform that eliminates the traditional separation between R&D and production.

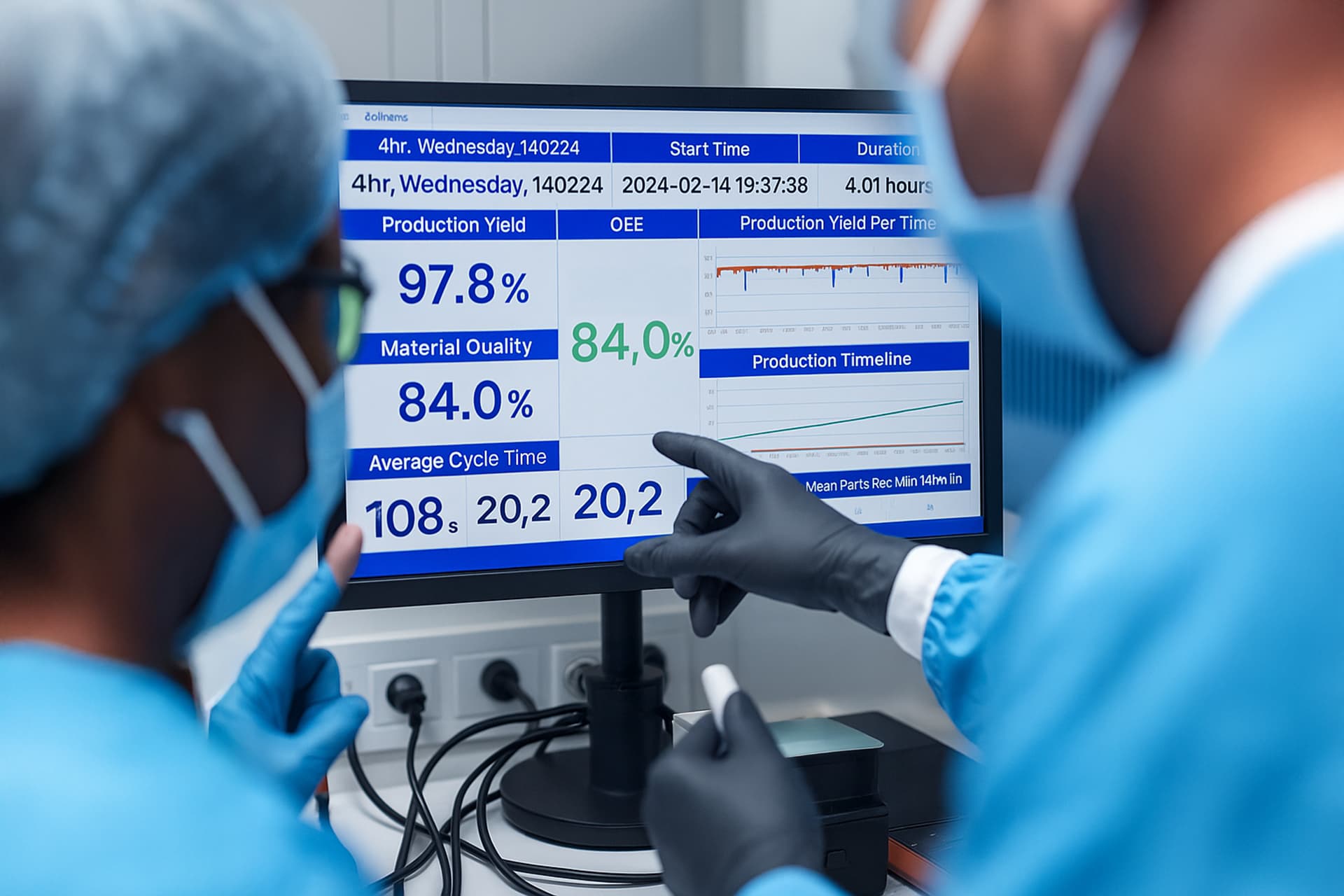

With Kaiku, engineers and operators work from a single source of truth. Process parameters, performance data, quality checks, and compliance records are visible in real time to everyone who needs them. The insights that drive a design of experiment can be the same ones that prevent a late-stage failure. Lessons from one line can instantly inform decisions across another.

Why It Matters for Leaders

- Shared Visibility, Faster Action: Kaiku aggregates every sensor, device, and line into one intuitive dashboard. Managers can spot anomalies before they cascade into shutdowns. Engineers can validate design choices in real-world conditions. Decisions happen earlier and with better context.

- Traceability Without Gaps: Every input, process step, and output is logged—across both development and production. This creates a bulletproof data trail that reduces compliance risk by up to 30%, ensures audit readiness, and builds confidence in continuous improvement.

- Predictive Intelligence at Scale: Kaiku applies advanced analytics to optimize scheduling, throughput, and resource allocation. The payoff: up to 20% reduction in downtime and 10–15% improvement in OEE.

By the Numbers

By the Numbers

Consider one glucose sensor line. A clogged nozzle halted production for nearly an hour. A new operator slowed changeover. Supervisors ran the machine below optimal speed to avoid risk. Inspectors later scrapped hundreds of units with uneven coatings. By the end of the shift, the line produced 10,620 sensors instead of 14,400—a loss of €5,600 in one day. More importantly, delays meant patients waited longer for critical devices.

The New Mandate for Industry 4.0 Leaders

Global supply chains are volatile. Regulations tighten every year. In this environment, R&D and production can no longer afford to operate as silos. Senior managers need end-to-end visibility, absolute traceability, and predictive intelligence to protect margins and accelerate growth.

Ginolis Kaiku delivers that foundation. It empowers teams to detect issues instantly, accelerate transfer from development to volume production, guarantee compliance without slowing operations, and scale confidently across plants and regions.

Smarter. Integrated. Resilient.

Kaiku turns fragmented data into a competitive edge—breaking down walls and building connected, intelligent manufacturing for the Industry 4.0 era.