In microfluidics, precision is everything—each microliter defines performance. Yet fragmented data and manual oversight often obscure process control. Ginolis Kaiku Data Collection unifies every dispensing parameter into one intelligent platform, delivering real-time visibility and traceability that drive smarter, faster, and more reliable microfluidic production.

Today’s blog is 712 words long, and a 10-minute read.

The Microliter Margin: Where Precision Defines Success

In industries where microscopic precision dictates success, from advanced diagnostics and cutting-edge medtech to intricate microfluidics, every microliter is critical. However, many operations still grapple with the inherent inefficiencies and hidden costs of fragmented data systems and manual logging.

The Hidden Cost of Fragmented Data

This fragmentation creates significant blind spots, impacting performance, compromising quality, and hindering robust traceability. When critical dispensing parameters like nozzle pressure or fluid viscosity fluctuate, the consequences may go unnoticed until post-production inspection or, worse, customer feedback. This reactive approachcharacterized by missed deviations, protracted changeover times, and delayed troubleshooting—accumulates substantial costs, leading to reduced yield, shipment delays, and potential compliance issues.

Kaiku: Closing the Gap

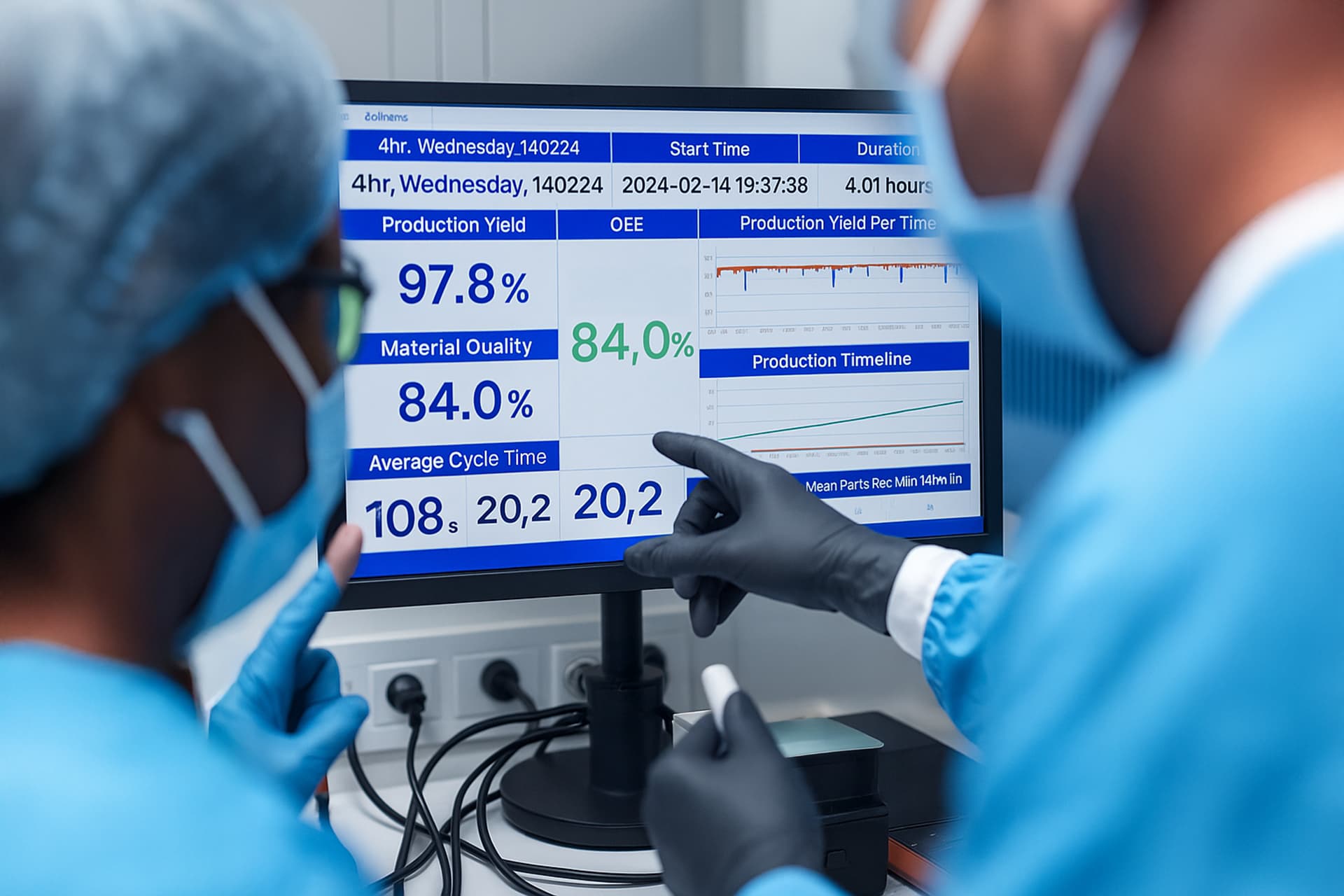

Ginolis Kaiku Data Collection is engineered to bridge these gaps, transforming dispensing operations by capturing, contextualizing, and unifying data from every device, sensor, and process step. It transcends mere data logging; Kaiku establishes a cohesive, real-time data layer that intricately links dispensing parameters, machine states, operator actions, and inspection results. This interconnectedness empowers proactive control, accelerates root cause analysis, and facilitates continuous process optimization. Whether the application involves dispensing sensitive reagents, high-performance adhesives, or specialized coatings, Kaiku ensures meticulous accountability for every dispense and unlocks actionable insights.

Why It Matters for Leaders

-

Real-Time Process Visibility: Kaiku provides intuitive visualizations of key dispensing metrics, including flow rate, pressure, and cycle time, across all operational stations. This enables operators and engineers to swiftly detect deviations before they impact product quality.

-

Uncompromised Traceability: Each dispense event is meticulously logged with precise timestamps, operator identification, and machine status, creating a comprehensive audit trail essential for regulatory compliance and internal quality assurance.

-

Scalable Efficiency Gains: By enabling the analysis of trends across multiple lines and shifts, Kaiku empowers teams to significantly reduce changeover times, minimize scrap, and optimize overall throughput, potentially achieving up to a 15% improvement in line efficiency.

Consider a real-world scenario on a cartridge filling line: a subtly misaligned syringe led to inconsistent volumes. Without real-time data oversight, this anomaly persisted for hours, resulting in hundreds of rejected units and significant delays to subsequent batches. With Kaiku’s immediate anomaly detection, the issue would have been flagged within seconds, averting an estimated €4,200 in losses during a single shift and safeguarding crucial delivery timelines.

Data-Driving Microfluidics – It is the Future.

In today’s landscape, where product complexity is escalating and compliance demands are tightening, precision dispensing necessitates more than mechanical accuracy; it requires intelligent, data-driven control. Manufacturers must achieve comprehensive visibility, rigorous traceability, and actionable intelligence at every stage of their operations.

Ginolis Kaiku Data Collection delivers this essential control. It equips teams with the capability to monitor, analyze, and enhance dispensing processes in real time, transforming raw data into decisive actions and ultimately, into superior operational performance. It sets the new standard for smart, responsive, and highly efficient dispensing solutions.