In this second article of the Viscosity Series, we test the Kaste Nano II pump with liquids up to 6 cP viscosity, including buffers and glycerol mixtures. The results show CVs below 0.6%, stable volume delivery across different types of liquids, and with minimal liquid waste —demonstrating reliable performance even with moderately viscous reagents.

Today’s blog is 1177 words long, and a 12 minute read.

Overview

In the first article of this Viscosity Series—“Viscosity: A Challenge for Low Volume Dispensing?”—we explored how liquid properties impact microdispensing performance. In this second installment, we shift the focus to the dispensing technology itself.

The core question driving this study is both simple and essential:

What can the Kaste Nano II pump reliably handle across a variety of liquids, viscosities, and dispensing conditions?

For applications where nano- and microliter-level accuracy and repeatability are critical, it’s not enough for a dispensing system to work under ideal conditions. It must deliver precision, volume stability, and efficiency across a range of real-world reagent types—water, solvents, biological buffers, and viscous mixtures alike.

This study evaluates the Kaste Nano II’s performance across these demanding scenarios, with a focus on three key metrics:

-

Precision: Low coefficient of variation (CV%) across different reagents and viscosity levels

-

Stability: Consistent volume output in both aspiration and bulk dispensing modes

-

Efficiency: High dispensing efficiency, with ~70% of aspirated liquid successfully delivered

The results show that the Kaste Nano II consistently meets these performance benchmarks—even under viscosity stress—making it a dependable platform for R&D labs and automation engineers handling a wide variety of fluids.

Experimental Setup

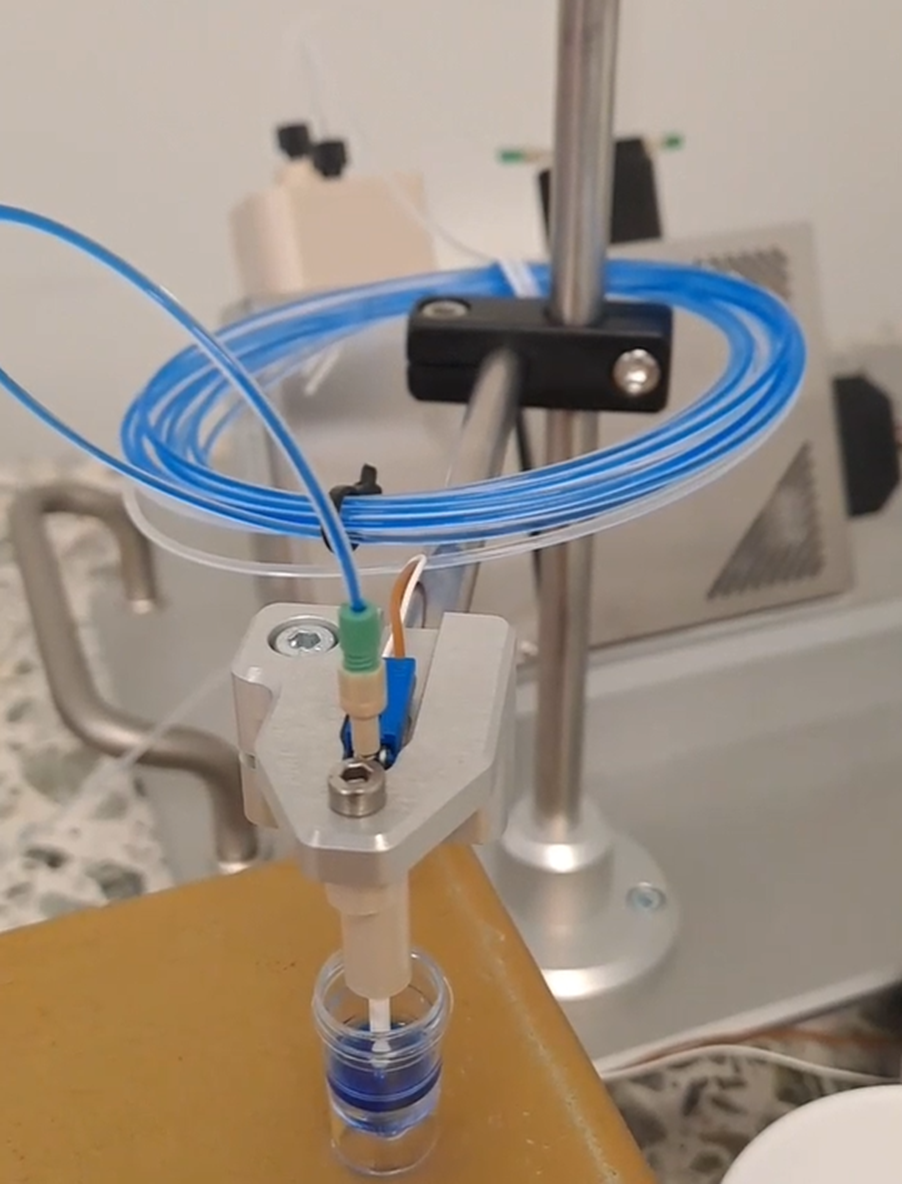

All experiments were conducted at Ginolis using a Kaste Nano II pump (S/N 5123002) paired with a Mettler Toledo XPR10 microbalance, mounted on a vibration-dampening stone table for optimal measurement stability.

System Configuration

-

Tubing: Standard 5.0 m FEP (0.03” ID)

- Dispensing Tip: 190 µm ceramic nozzle

-

Degasser: 480 µl vacuum chamber

-

Valves: Standard front- and back-side valves

-

Dispense Protocols:

-

Aspirate-dispense: 2200 µl is aspirated through dispensing tip into tubing, 1500 µl of aspirated volume is dispensed

-

Bulk priming: Dispensed liquid is primed through the pump from reservoir bottle

-

Tested Liquids

-

Low-viscosity: Water, ethanol (denatured with n-butanol)

-

Buffers: PBS and TBST (0.1% Tween® 20) with blue dye

-

Moderate-viscosity: Glycerol-water mixtures (50% ~6 mPa·s)

Observation #1

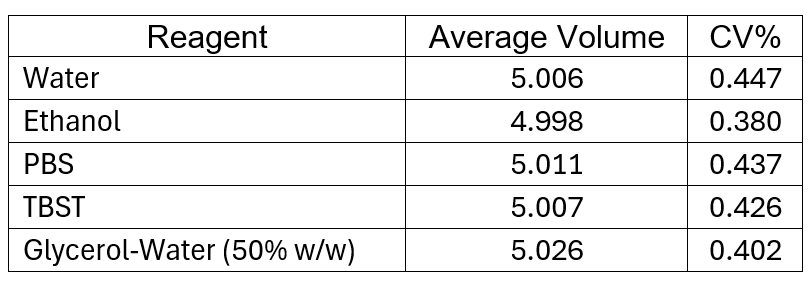

Low CV% Across All Reagents and Viscosities

The Kaste Nano II maintained consistently low CV values (<0.6%) across all tested fluids—ranging from water and ethanol to more complex buffers and glycerol-water blends.

-

Water & Ethanol: CVs typically <0.5%

-

PBS & TBST Buffers: Maintained identical precision to water, despite surfactant-induced surface tension shifts

-

Glycerol Mixtures: With this setup and a concenration of 50% glycerol showed no loss in repeatability, validating performance under moderate viscosity stress, with this setup

Takeaway: Regardless of fluid characteristics, the Nano II delivered highly consistent volumes, critical for assay reproducibility and system robustness.

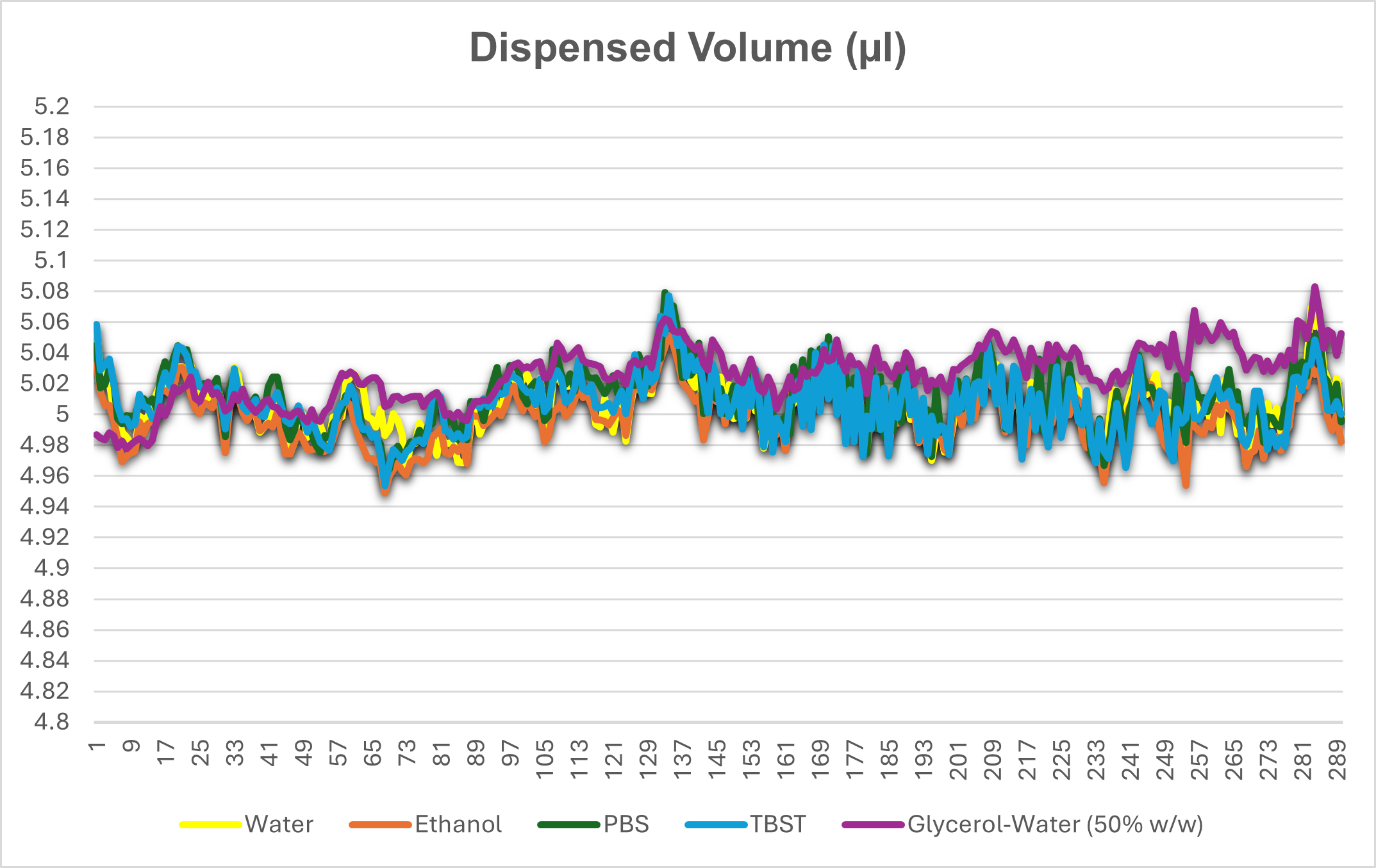

Observation #2

Stable Volume Delivery in Aspiration and Bulk Modes

Both aspiration-dispense and bulk priming protocols yielded remarkably stable dispensed volumes. Identical dispensing parameters were used with all the liquids and runs. No significant variation was observed in individual dispense volumes over repeated runs, confirming:

-

Mechanical repeatability across sessions and operators

-

No drift across daily or weekly operations

-

No sensitivity to switching between reagent types

For both aspiration dispensing (buffers, glycerol mixture) and bulk priming (ethanol and water) volume constancy was preserved, validating the internal control mechanisms of the pump.

Design Implication: This level of consistency reduces the need for recalibration, enabling faster experimental setup and validation for lab automation workflows.

Observation #3

High Dispensing Efficiency (~70%) Across Fluids

Dispensing efficiency was defined as the percentage of aspirated volume successfully delivered to target without excess dead volume, waste, or loss due to dilution or air inclusions.

-

Across all reagents, ~70% efficiency was observed – 2200 µl aspirated, 1500 µl dispensed

-

Efficiency remained constant regardless of liquid viscosity

This level of efficiency reflects optimal flow paths, and tubing geometry, making the Nano II suitable for workflows involving precious or limited-volume reagents.

Operational Benefit: Reduced reagent loss directly impacts cost per test and improves throughput reliability, especially in diagnostics or biopharma environments.

Why This Works

The Kaste Nano II’s performance is underpinned by its positive displacement pumping mechanism, which provides:

-

Volumetric precision unaffected by viscosity fluctuations

-

Mechanical resilience, with consistent performance over long-term operation

While pressure-driven systems exhibit sensitivity to viscosity and back-pressure, the Nano II maintains stable output by mechanically isolating the dispense volume from these external variables.

For fluids >20 mPa·s, adjustments such as larger-diameter tubing or contact dispensing modes are recommended to maintain pressure stability.

Bottom Line – Why It Matters

In R&D and precision manufacturing environments, the smallest inconsistencies in fluid handling can compound into significant downstream issues—whether in assay variability, failed runs, or wasted reagents.

The Kaste Nano II’s ability to dispense diverse reagents with low CV, high volumetric consistency, and minimal waste means:

-

Fewer failed experiments due to irregular dosing

-

Reduced need for re-calibration or manual intervention

-

Accelerated validation of new reagents or protocols

-

Lower reagent costs and higher operational yield

For engineering teams, this translates to faster time-to-system integration and greater confidence in automated workflows. For R&D and business leaders, it delivers scalable performance across applications, from early-stage assay development to high-throughput production.

The Nano II is not just precise—it’s reliably precise, even under variable conditions. That distinction matters when scaling up science to production.

Conclusion

The Kaste Nano II pump demonstrates precision, stability, and efficiency across a wide range of liquid types and viscosities. Whether operating in aspiration or bulk dispensing mode, the system consistently delivers:

-

Low CV% (<0.6%) across all fluids

-

Constant volume per dispense with minimal variation

-

~70% dispensing efficiency, even under challenging conditions

For research and development teams prioritizing accuracy, reproducibility, and flexibility, the Nano II provides a technically robust and integration-ready solution for demanding fluidic environments.

Up next in the Viscosity Series: tackling high-viscosity liquids and the engineering strategies that make it possible. Stay tuned!