How far can precision go under viscous stress? Part 2 pushes Kaste Nano II into high-viscosity territory with larger tubing: CVs <0.6%, 5-µl measurements, ~70% efficiency across water, buffers, ethanol, glycerol. Positive displacement fluidics conquers back-pressure.

Today’s blog is 772 words long, and a 8 minute read.

Overview

In this second article of the Viscosity Series, we asked oursleves What can Kaste Nano Handle? We tested the Kaste Nano II pump with liquids up to 6 cP viscosity, including buffers and glycerol mixtures. Results show CVs below 0.6%, stable volume delivery across different types of liquids, and with minimal liquid waste —demonstrating reliable performance even with moderately viscous reagents.

Is that the limit? What happens if we push this further?

This installment explores the Kaste Nano II’s performance with high-viscosity liquids (up to 20 mPa·s., equivalent to 20 cP)

The Core Question

At the outset, we have two questions that determine the efficacy of our solutions beyond the initial analysis:

- How does the Kaste Nano II perform when viscosity increases beyond the original 6 cP?

- What engineering adjustments ensure precision and repeatability under these demanding conditions?

Experimental Setup

Configuration

- Pump: Kaste Nano II (S/N 5123002)

- Tubing: Both standard (5.0 m, 0.03” ID FEP) and custom larger-diameter (1/16” ID FEP, 1.2 m) tubing were tested to reduce back-pressure for viscous liquids.

- Dispensing Tip: 190 µm ceramic nozzle

- Degasser: 480 µl vacuum chamber

- Valves: Standard configuration

Protocols

- Non-contact dispensing

- Aspirated volume: 2200 µl

- Dispensed volume: 1500 µl per run

Tested Liquids

- Water, ethanol, PBS and TBST buffers (with dye)

- Glycerol-water mixtures (50% and 69% glycerol, up to 20 mPa·s)

- Ethanol (for volatility and low surface tension)

Observation #1

Precision Maintained across the Viscosity Range

Regardless of the liquid – buffers, reagents, and ethanol – our performance didnt flinch. We mainted CVs below 0.6% confirming high precision across the viscosity range.

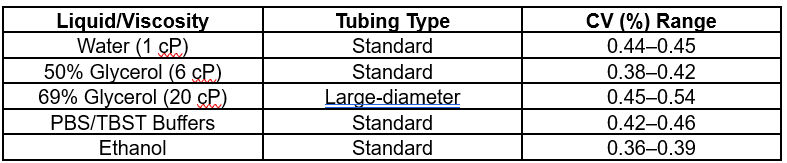

- With standard tubing, the Kaste Nano II achieved CVs of 0.38–0.45% for water and 0.38–0.42% for 50% glycerol (6 mPa·s).

- Using larger-diameter tubing, the pump handled 15–20 mPa·s (equivalent to 15-20 cP) glycerol mixtures with CVs of 0.45–0.54%

Takeaway: Regardless of fluid characteristics, the Nano II delivered highly precise volumes with a tight Coefficient-of-Variation (CV), critical for reagent optimization and waste minimization.

Observation #2

Stable Volume Output and Efficiency

Another hallmark of our dispensing solution was preserved: the ability to dispense stable volumes irrespective of the liquid type.

- Across all protocols, the average dispensed volume per measurement was consistently ~5.0 µl, with minimal drift or variation between runs.

- Dispensing efficiency (defined as dispensed/aspirated ratio) remained high (~70%) for all tested fluids, regardless of viscosity.

Operational Benefit: Regardless of fluid characteristics, the Nano II delivered highly consistent volumes, critical for assay reproducibility and system robustness.

Observation #3

Robustness to Liquid Properties

Throw a liquid, we will handle it. This is because of our patented displacement mechanism

- Kaste Nano II’s positive displacement mechanism ensured that changes in viscosity or surface tension did not affect volumetric accuracy.

- Buffers with surfactant (TBST) and volatile solvents (ethanol) were dispensed with the same precision as water, demonstrating the system’s versatility.

Operational Benefit: Regardless of fluid characteristics, Kaste Nano works, so you don’t have to change your setup every time you change your reagent.

Practical Implications

- For R&D and production labs: The Kaste Nano II can reliably handle a wide range of viscosities, from water to highly viscous glycerol mixtures, with minimal parameter adjustment.

- For automation engineers: Evaluate setup and tubing for high-viscosity or challenging fluids to ensure consistent delivery.

- For cost-conscious workflows: High dispensing efficiency and low CVs mean less reagent waste, fewer failed runs, and no need for recalibration.

Why This Works

- Aspirated through the tip and dispensing is limited by pressure and droplet formation at high viscosities.

- Tubing and setup optimization, especially with larger tubing, reduces back-pressure and ensures the entire aspirated volume can be delivered without loss or instability.

- The positive displacement design isolates the dispensed volume from viscosity-driven pressure fluctuations, maintaining accuracy.

For viscous liquids, adjustments such as larger-diameter tubing are recommended to maintain pressure stability.

Bottom Line – Why Should You Care

The Kaste Nano II pump demonstrates precision, stability, and efficiency across a wide range of liquid types and viscosities. Whether operating in aspiration or bulk dispensing mode, the system consistently delivers:

-

Low CV% (<0.6%) across all fluids

-

Constant volume per dispense with minimal variation

-

~70% dispensing efficiency, even under challenging conditions

For research and development teams prioritizing accuracy, reproducibility, and flexibility, the Nano II provides a technically robust and integration-ready solution for demanding fluidic environments.

Up next in the Viscosity Series: Strategies for microdispensing of liquids – what should you do? Stay tuned!