Product Validation Services

We help assess risks for both operators and end-product integrity, ensuring that your automation plans align with quality requirements.

From early-stage feasibility to full-scale production and long-term system performance, our expert services ensure precision, compliance, and confidence at every step.

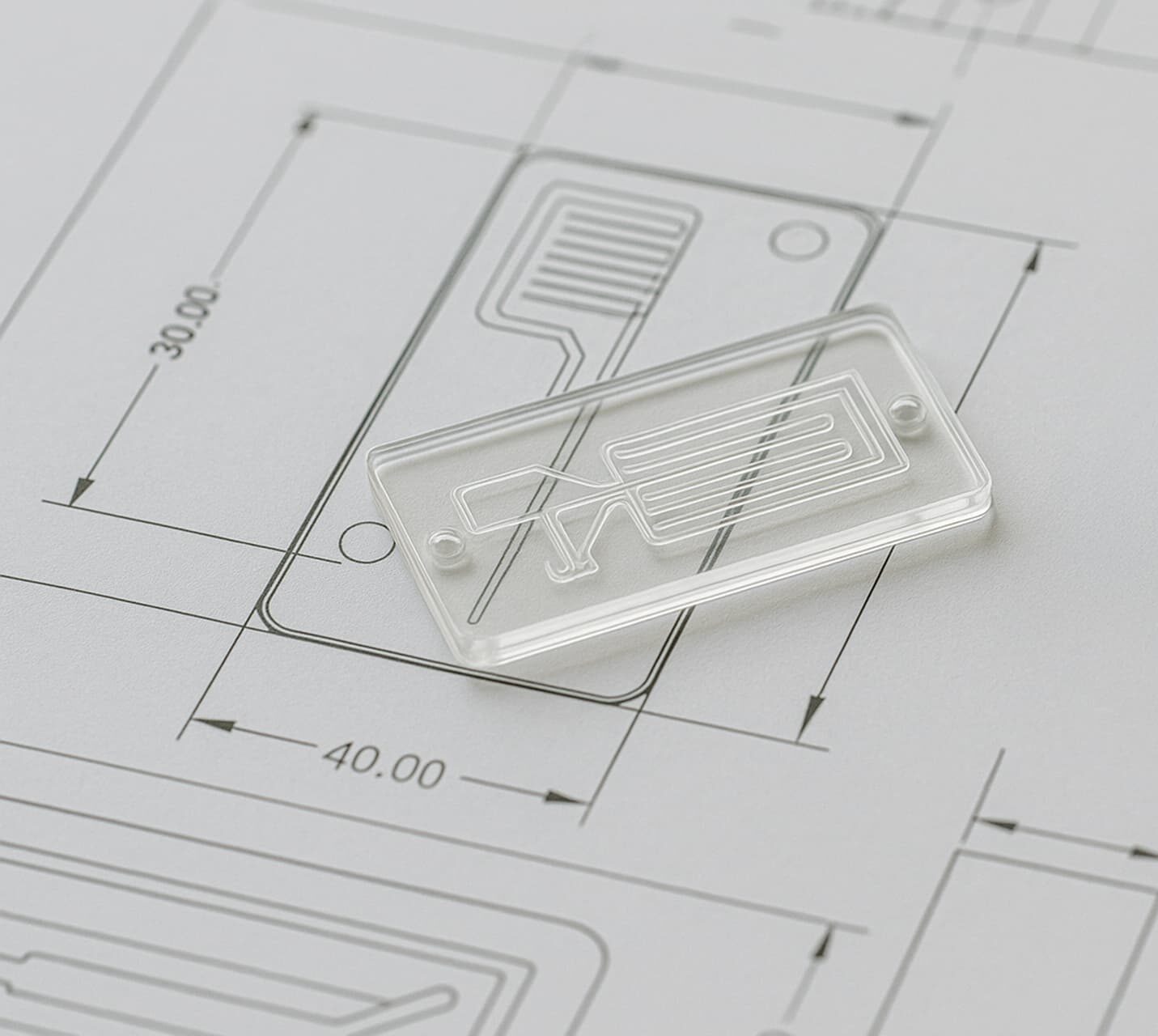

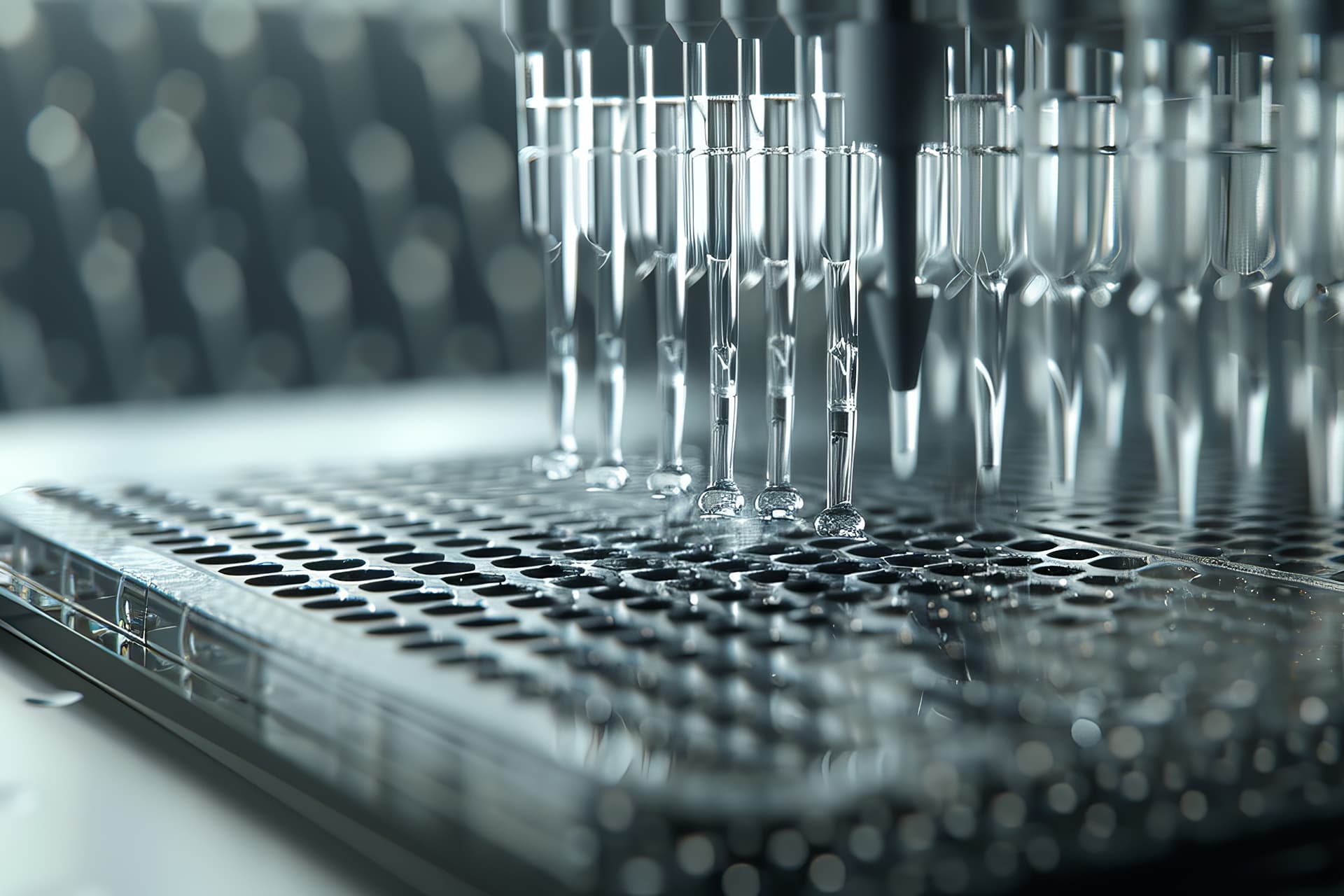

At Ginolis, we don’t just deliver automation systems—we partner with you to optimize every stage of your manufacturing lifecycle. Whether you’re implementing high-precision microfluidic assembly, scaling lateral flow device (LFD) production, or seeking automation compliance support, our comprehensive services are designed to enhance efficiency, quality, and operational continuity.

Our Consultation-led feasibility services help you evaluate and plan automation strategies with precision, objectivity, and production automation awareness. At Ginolis, we act as an independent authority, free from platform or vendor constraints, allowing us to focus solely on what works best for your product and production goals.

Whether you’re launching a new diagnostic product, scaling an existing microfluidic solution, or validating a lateral flow device assembly, our structured feasibility process ensures every technical and business decision is informed, efficient, and aligned with your long-term objectives.

A comprehensive deep dive into your production setup, focusing on process flows, risk areas, scalability potential, and automation readiness

We provide honest, technology-agnostic insights, recommending the most suitable solutions based on your unique needs. Whether integrating systems from multiple vendors or incorporating Ginolis technologies, we ensure your requirements are fully met.

Focused on CAPEX optimization and throughput enhancement, we provide advice on the right product and automation mix to help transition from R&D to production smoothly. We can also evaluate different regulatory regimes to provide an initial assessment of compliance requirements.

We help assess risks for both operators and end-product integrity, ensuring that your automation plans align with quality requirements.

Our experts support you in mapping critical processes, optimizing line balancing, and developing a sound machine selection strategy tailored to your production goals.

We assist in organizing and preparing the technical documentation needed for market access, and any testing/documentation for CE marking as requested.

We evaluate your current infrastructure to identify opportunities for cloudification and smarter production insights, leveraging Kaiku™ to support your journey toward connected manufacturing.

Joint workshops and site evaluations to uncover real needs, hidden inefficiencies, and compliance challenges

Technical concepting that aligns automation with product characteristics and cleanroom integration requirements

Mechanical, electrical, and software engineering brought together to build a cohesive, validated solution

Fast, cleanroom-friendly installation with validation protocols, operator training, and Kaiku integration

Our vendor-agnostic Kaiku™ analytics platform empowers customers to analyze, predict, and optimize R&D setups and processes through data-driven insights. By streamlining the transition from R&D to production, Kaiku™ significantly reduces time and complexity in technology transfer, accelerating time-to-market.

From small-batch production to fully automated diagnostics manufacturing lines, Ginolis delivers precision-engineered solutions tailored to your roadmap.

Our After Market Services (AMS) are designed to ensure your Ginolis automation systems operate at peak performance—day in and day out. Whether you’re running high-precision microfluidics equipment or a complete lateral flow device assembly line, our AMS programs are tailored to support operational continuity, regulatory compliance, and long-term value.

Avoid costly downtime and maintain system integrity with scheduled, data-driven maintenance. Using historical performance data and real-time monitoring with Kaiku™, we identify and address potential issues before they impact production.

Unexpected breakdowns require swift action. Our certified service engineers are equipped to provide both remote troubleshooting and rapid on-site response to minimize downtime and restore operations quickly.

Technology evolves—so should your automation. We assess your installed base and implement hardware and software upgrades that improve reliability, extend equipment lifespan, and ensure continued compliance with evolving industry standards.

Leverage our secure remote access capabilities to reduce service costs and response times. We can perform diagnostics, updates, and system health checks without interrupting your cleanroom operations.

We offer customized training sessions and comprehensive documentation packages tailored to your system, team, and regulatory requirements. Empower your operators and maintenance staff with the skills and knowledge to maximize system efficiency and safety.

Ensure critical components are always on hand. We offer speedy delivery, proactive parts replacement planning, and inventory management support to help you avoid unnecessary downtime and supply chain disruptions.

Support requests are managed efficiently through our Freshdesk ticketing system at https://ginolis.freshdesk.com/support/home. Our service agreements ensure priority handling and prompt, effective support tailored to your needs.

Whether you’re exploring automation for the first time or scaling advanced diagnostic manufacturing, Ginolis is your independent partner in automation success. You can also send a simple inquiry to info@ginolis.com.