Modular Automation Technology for Diagnostics Production

At Ginolis, we transform manufacturing complexity into simplicity with our adaptive automation platforms – ensuring 50% faster integration and 30-minute product changeovers for your evolving needs.

Why Leading Manufacturers Choose Ginolis

Our Automation Stands Out

- No vendor lock-in: Our open-architecture Xanthia Platform integrates seamlessly with your existing equipment, slashing commissioning time by 50%.

- Unmatched flexibility: Switch products in 30 minutes using Intelligent Parts Kits and self-adjusting software – no engineering team required.

- Proven reliability: 150+ automation systems deployed across life sciences, electronics, and consumer goods sectors.

Your Production Advantages

- 90% faster training with intuitive operator interfaces designed by ergonomics experts

- Zero downtime transitions between product variants or batch sizes

- 30% lower TCO compared to traditional automation systems

- Future-ready scalability – start with our LFDA-1 standard machine and upgrade effortlessly

We Simplify Automation

- Smart Foundation: Build on our Ginger Automation OS – the brain that harmonizes robots, vision systems, and third-party devices.

- Precision Configuration: Choose between off-the-shelf solutions or custom Xanthia-based systems tailored to your workflow

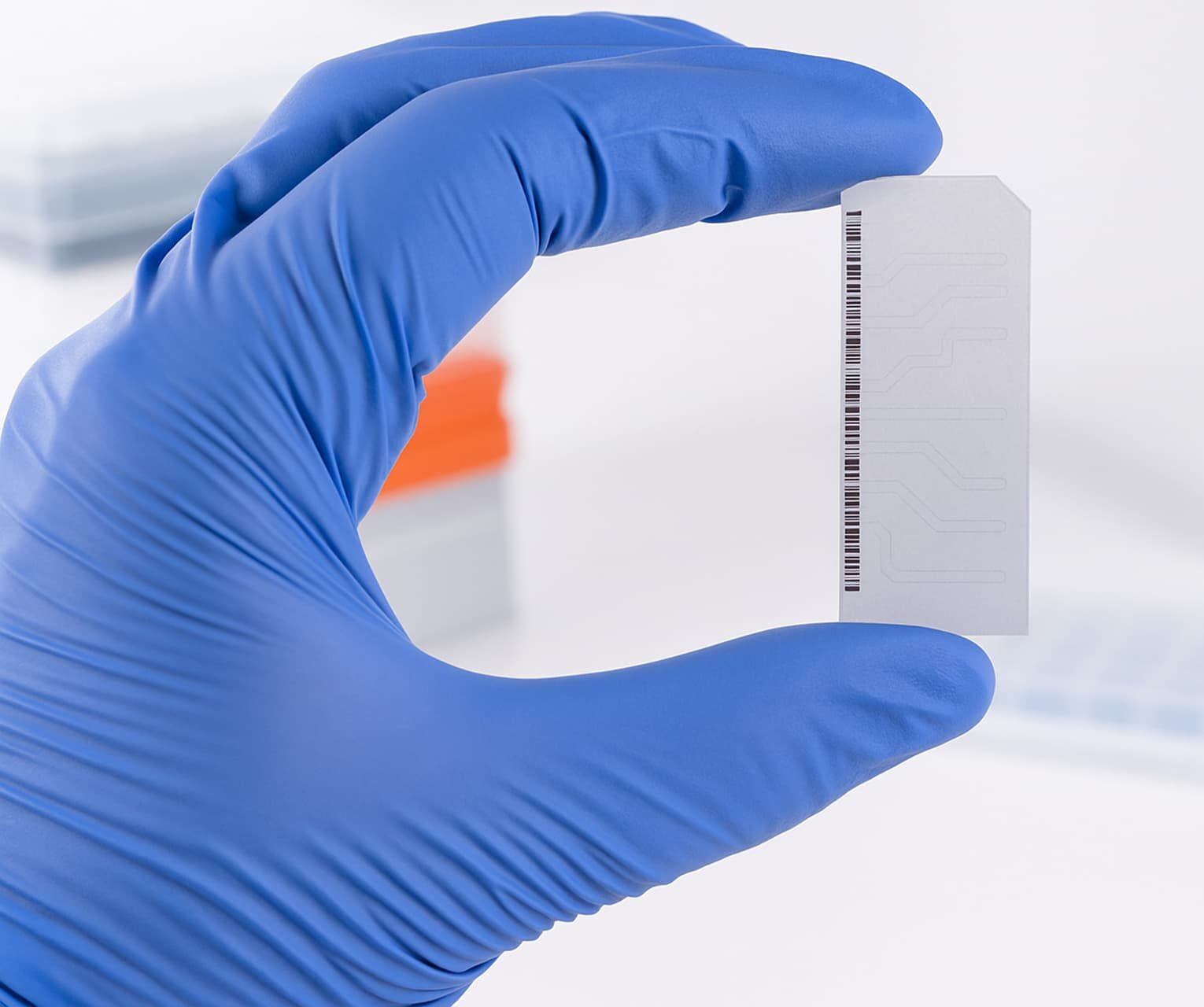

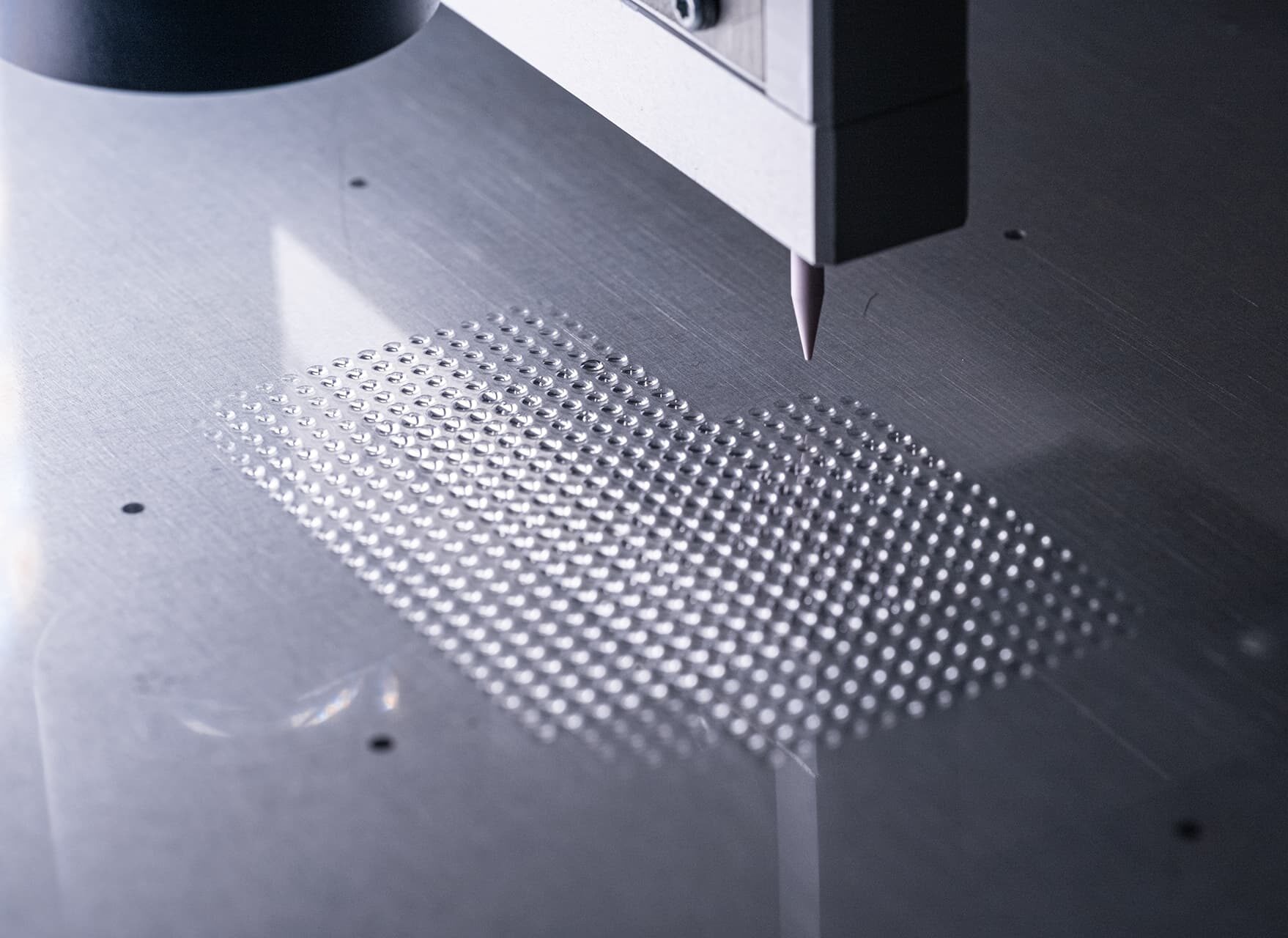

Precision Liquid Dispensing and Handling from R&D Laboratories to High-Throughput Production

Ginolis Kaste product family enables precision nano to microliter dispensing of valuable, assay critical reagents. With factory calibration, Ginolis Kaste ensures accurate doses from day one. Our experts appreciate the reagent dispensing considerations, always aspiring to find best solution for your product. With Ginolis Kaste and the complimenting technologies we can cover a wide range of different reagent dispensing applications, including a wide range of different reagents and solvents, viscosities and environmental needs.

At the heart of Ginolis Kaste, is the Piezo Motor Bellows technology. The technology allows for frictionless operation and a precision of displacement that is unmet in competing dispensing technologies. The Kaste Nano pump has built in intelligence, making for easy integration and care-free operation even at nanoliter doses

- Precise dosing of your valuable liquids in volumes as low a 1 nL per dose with low variability as low as sub-1% CV.

- Factory calibration and the built-in feedback loop of the Kaste Nano eliminate the need for time-consuming daily calibration procedures of competing systems.

- Ginolis experts have a large knowledge base of dispensing technologies and are happy to find the one matching your needs.

Transform Your Quality Control with Intelligent Technology Integration

Why Choose Our Integrated Approach?

- No single-technology limitations: We blend AI-driven machine vision, high-precision confocal sensors, and smart sensor networks from global leaders into unified systems.

- Proprietary integration expertise: Our “technological glue” connects hardware and software seamlessly, ensuring flawless communication between components that others can’t combine.

- Future-proof solutions: Access our curated library of modern technologies, continuously updated with innovations from trusted partners worldwide.

Your Operational Advantages

- 90% cost reductions by eliminating redundant processes and optimizing workflows

- Zero unsolvable challenges – we specialize in overcoming “impossible” monitoring tasks

- 24/7 adaptive systems that self-calibrate to production line variability

- Risk-free implementation with proven ROI models from 100+ successful deployments

Our Technology Orchestration Process

- Precision Matching: We identify the optimal mix of vision systems, sensors, and AI tools for your specific needs

- Intelligent Fusion: Our engineers develop custom interfaces and data synthesis algorithms

- Continuous Optimization: Advanced machine vision systems that are designed to be immune to changes in the operating environment.

- Full Product and Process Traceability with Ginolis Kaiku

Let’s Optimize Together

Whether you’re exploring automation for the first time or scaling advanced diagnostic manufacturing, Ginolis is your independent partner in automation success. You can also send a simple inquiry to info@ginolis.com.